Flange Isolation Kits includes an isolation gasket, several isolation sleeves, several isolation washers and metal washers, and the dimensions of these components are designed and produced according to the corresponding flanges. Flange Isolation Kits are commonly used in industries such as oil and gas production, processing, transportation and power generation.

Gasket Classification

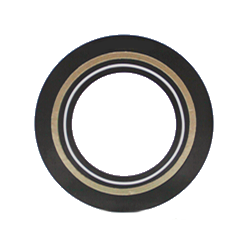

The fire-safe gasket incorporates a primary spring-energized PTFE seal and a secondary camprofile seal. Both seals are seated within a retainer made of epoxy-bonded stainless steel. Under normal operating conditions, the secondary seal functions as a backup; in the event of a fire, it becomes effective upon failure of the primary seal.

The high-pressure gasket is constructed with a stainless steel core bonded with glass-reinforced epoxy. Precision seal grooves are machined into the core, into which spring-energized PTFE seals are installed. The gasket is suitable for flange pressure classes up to 2500 lbs.

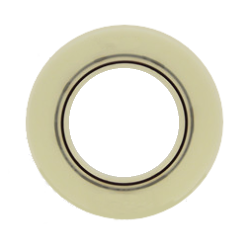

The medium-pressure gasket consists of two grooves on both sides, into which either elastomeric sealing elements or PTFE seals are installed. It is suitable for a wide range of services, including water, gas, oil, and hydrocarbons.

The low-pressure gasket is manufactured from neoprene rubber–faced phenolic material. It is suitable for flange pressure classes up to 300 lbs and for operating temperatures up to 75 °C.

Phenolic gasket is specifically designed to fit into the ring groove of ring-type joint (RTJ) flange. It is manufactured from a medium-weave, fabric-reinforced phenolic material and is produced in accordance with ANSI and API specifications.

Sleeves & Washers

To achieve complete electrical isolation at flange connections, isolation sleeve and washer sets are required for use with our isolation gaskets.

Isolation sleeves shall be manufactured from materials with low water absorption (due to thickness limitations), high dielectric strength, and low cold-flow characteristics, and shall be suitable for the service conditions of the specific application.

Isolation washers shall be manufactured from materials with high compressive strength, low water absorption, high dielectric strength, and low cold-flow characteristics.